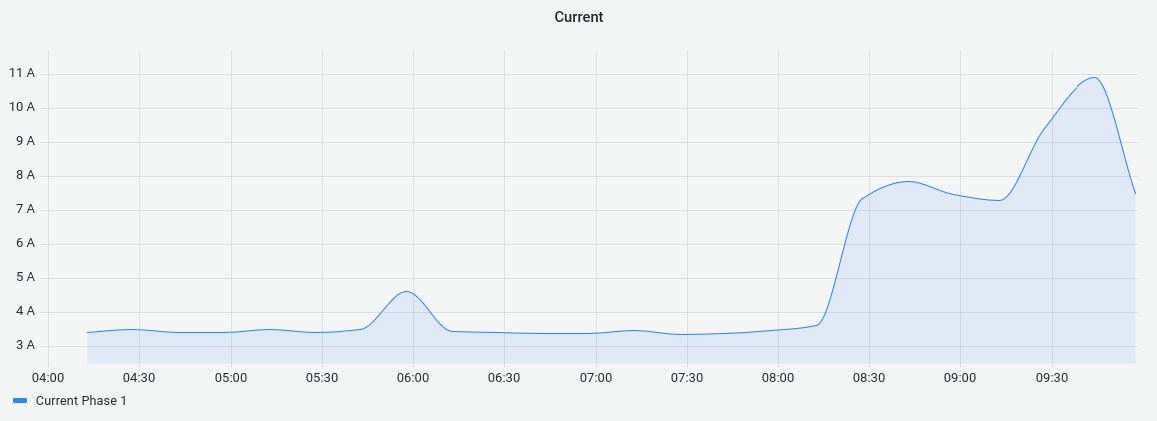

Electricity

Monitoring electricity usage is crucial for businesses to save on costs and helps identify inefficiencies. Our sensors can directly track electricity through the use of Modbus connections to existing smart meters or Current (CT) Clamps. This information is consolidated in one place, alongside other parameters, making it easier to compare month-to-month usage.

Electricity monitoring enables the early detection of anomalies, ensures correct billing, and eliminates inefficiencies within your business. Current (CT) Clamps delve deeper into machinery uptime, downtime, efficiency, and running costs. Current Clamps are sensors which clamp around power cables of meter panels and machinery to monitor the electric current running through that cable. This can identify areas of high usage and waste, displaying which if any machines have a high running cost and low efficiency. This data can be utilised to calculate; power factor, CO2 emissions, and cost over time.

Order your OpenSmartMonitor sensor via the Devtank website.

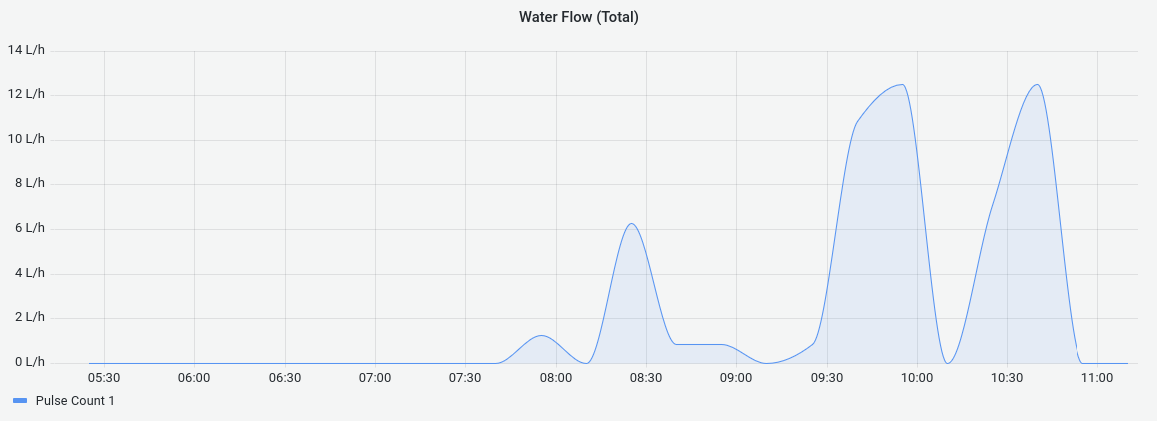

Water monitoring facilitates waste reduction and sustainability efforts throughout a business, by early detection of leaks, optimizing usage, and identifying inefficient fixtures. This further contributes to cost savings, compliance with local regulations, and environmental stewardship. Moreover, it ensures reliable water availability during droughts and enhances operational efficiency.

Water monitoring with OpenSmartMonitor uses flow meters connected to our sensors via Modbus. Flow meters are smart water meters installed onto hot and/or cold water pipes, measuring water flow (Litres Per Hour) and volume (Metres Cubed). Monitoring both hot and cold streams of water within your building will help determine the location of inefficiencies or potential leaks.

Gas

Gas serves as a crucial energy source in manufacturing, but monitoring its usage is equally vital. By closing tracking gas consumption, businesses can identify insulation and machinery inefficiencies, and spot potential leaks. This proactive approach not only mitigates safety risks, but also leads to substantial cost savings and environmental benefits. Our sensors monitor gas through Modbus connections to existing smart meters or flow meters.

Case Study

Lindhurst Engineering came to our team in search of a solution to their high energy bills and inefficiencies. We happily set them up with an army of sensors around their factory to enable environmental monitoring, machine monitoring, and energy monitoring. Environmental monitoring gave insights into how clean and safe their workplace is, whilst machine and energy monitoring provided answers to where they are wasting energy and how to save on costs. Now driving their business towards a more sustainable engineering factory their data already suggests they could save £25k a year in energy costs.

Order your OpenSmartMonitor sensor via the Devtank website.

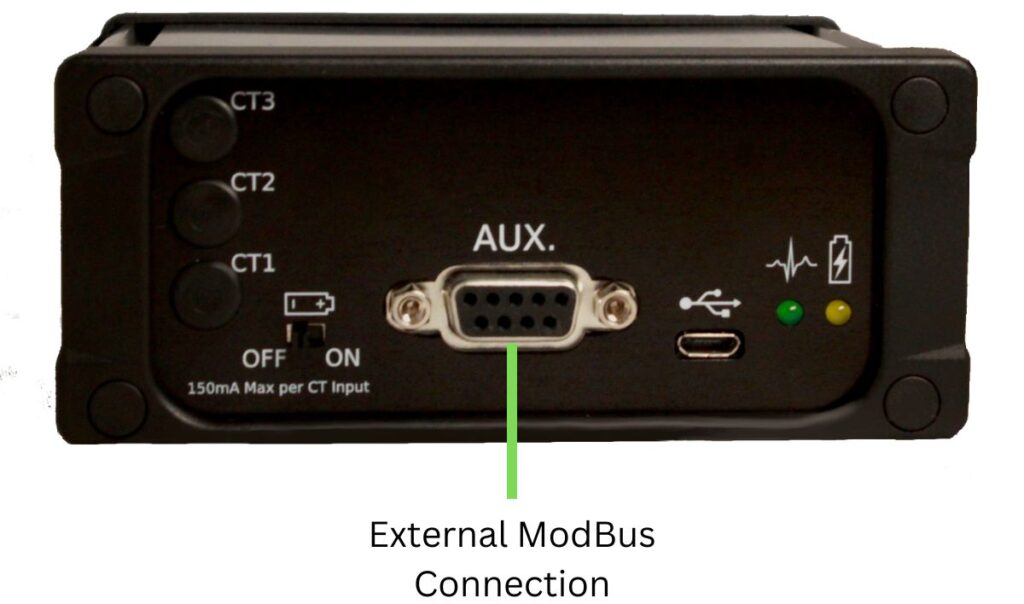

How does it work?

Our OpenSense allows for easy energy monitoring using only one sensor. If you already have sub-meters, simply connect them to our sensors via a MODBUS RTU RS485 connection to obtain data directly from your meters. For water monitoring, you can use an external pulse input, while gas usage can be measured with our digital pulse input.

Contact our team for more information and discuss how it could benefit your business