What Is Environmental Monitoring In A Business?

Whilst most of us know of environmental monitoring being used by city councils and certain construction sectors to monitor the impact they are having on the world, as well as the conditions of a site, it is also beneficial for other industry sectors to utilize this power. Environmental Monitoring within businesses from Factories to shops and offices will enable you to improve your workplace comfortability and safety. Monitoring parameters such as temperature, sound levels, humidity, and air quality will provide you insights in to how clean your workspaces are, and prevent unwanted effects on staff and your building. This page will detail everything our OpenSense can do for your environment and why each parameter can be important.

Why Environmental Monitoring?

Our sensors come with out the box with environmental parameters such as; temperature, air quality, humidity, sound and light. Environmental Monitoring can help you maintain a comfortable and safe workplace whilst also giving you deeper insights into your building’s efficiencies.

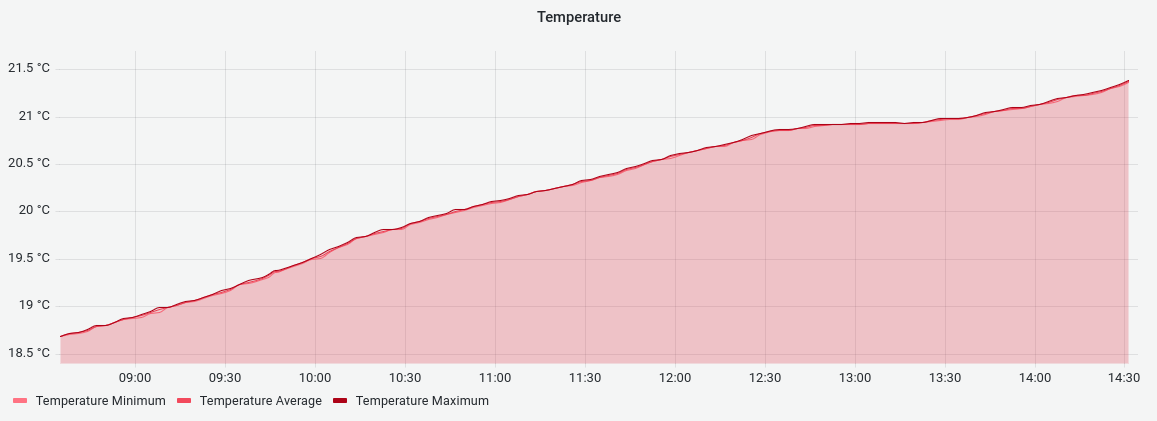

Temperature

Temperature monitoring is key when it comes to ensuring employee comfort, energy efficiency, and equipment performance. Our sensors uses a 3-in-1 temperature, humidity, and air quality sensor which is built into the main board. For external temperature monitoring, monitoring of loft spaces or inside machinery, temperature probes can be utilized.

Certain industries have different reasons for monitoring temperature whether that would be for clean rooms, food production, or the furniture industry as materials react differently under different temperatures. For example, if a newly made armchair is stored within a warehouse where the temperature drops dramatically overnight, the wood can bow/distort, but also the outer materials may expand resulting in sagging textiles.

Contact our team for more information and discuss how it could benefit your business

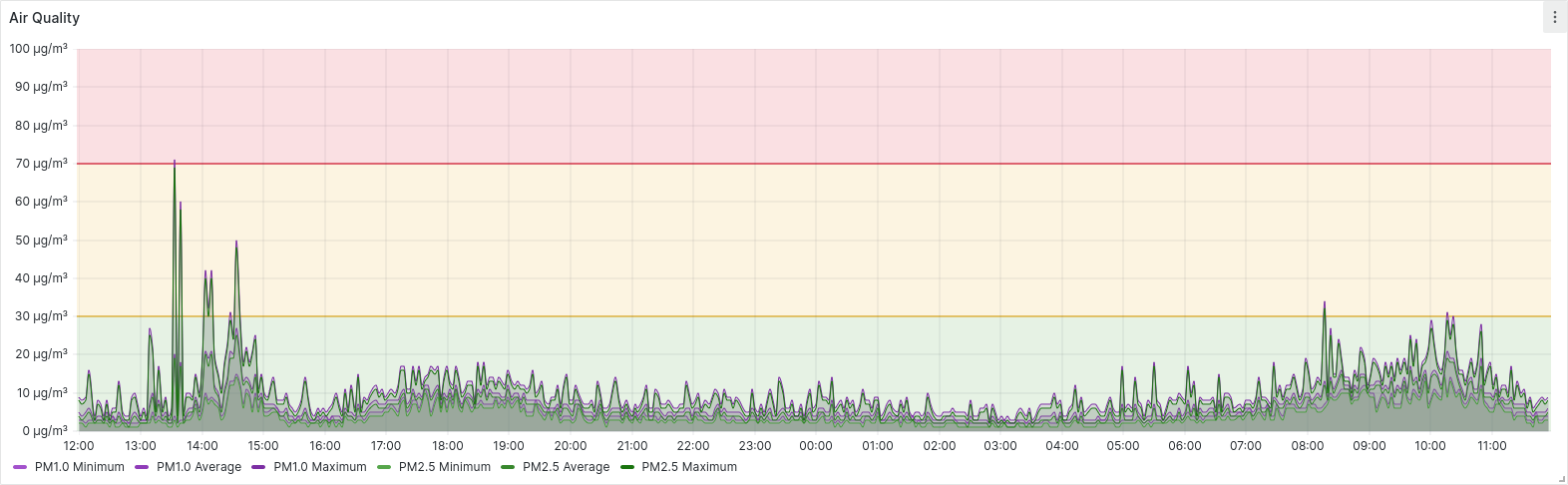

Air Quality

Monitoring and maintaining your air quality is essential for the health and safety of staff members, especially in manufacturing environments which are prone to airborne toxins and dust. Regular monitoring enables business to deploy adequate ventilation where required, preventing health issues amongst employees, and aiding with compliance audits. Automated alerts will further enhance safety measures taken to prevent staff being exposed to a high level of particulates and toxins. Ensuring your air quality is kept to a good standard will improve the overall health of the workforce and improve their productivity.

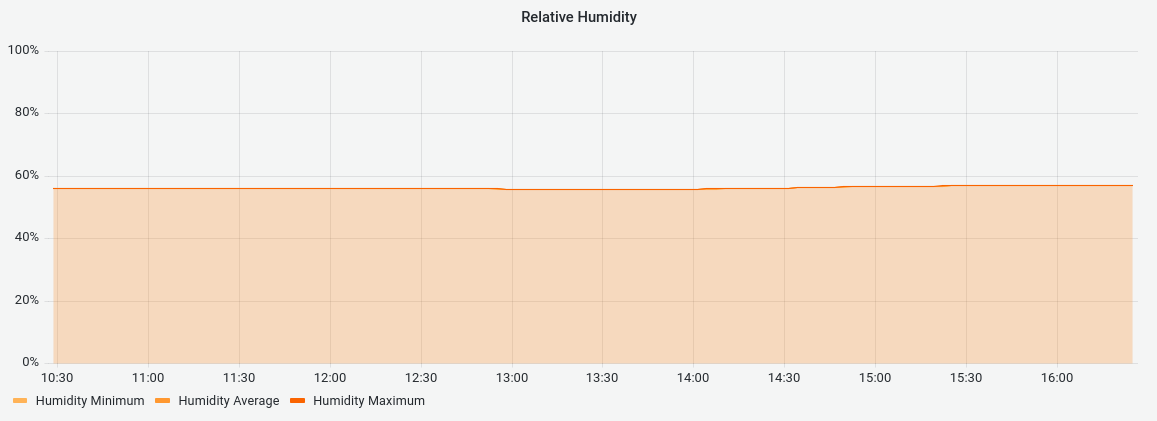

Humidity

Ideal humidity levels can be seen between 45% and 65%

A balanced humidity level is key to employee comfort and building health. Monitoring and maintaining ideal humidity levels prevent discomfort, material degradation, and mold formation. By implementing building improvements and utilizing dehumidifiers, businesses can create a conducive environment that supports productivity and longevity.

Humidity below 40% will make rooms appear hot and dry, resulting in headaches, dryness of the mouth, and possible skin dryness. Similarly, buildings can see materials drying out such as flaking plaster, and will have an increase in static buildup. Levels of %70 and above will feel heavy and cold, with walls more likely to develop mould and condensation. Humidity in short measures the level of water vapor within the air, hence why a higher humidity results in mould and condensation, as their will be an increase in water vapor.

Case Study

Trimmings By Design being a long-lasting textiles company, steeped in history, wanted to improve their workplace environment to make it as comfortable as they could for their staff. With our OpenSense sensors, they were able to monitor their real-time and historic environmental data, providing them with insights into potential improvements to their building and machine placements. One machine in particular can reach very high temperatures and with no proper ventilation can result in the room and staff feeling this heat increase. By enabling environmental monitoring in different areas of their building, they found the coolest area to move this machine to improve its working environment. They also measured their sound levels across their site making changes to where certain machinery sat to equally disperse noise levels.

Order your OpenSmartMonitor sensor via the Devtank website.

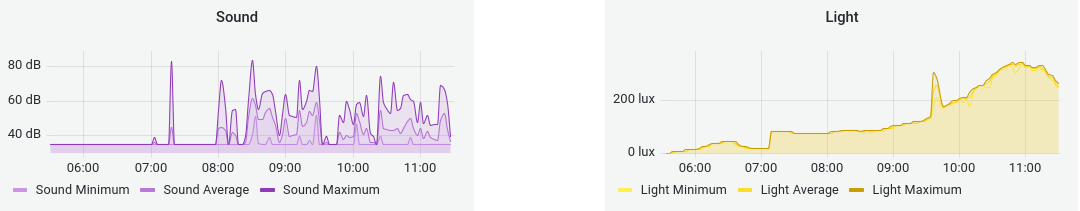

Sound Levels

Effective sound monitoring safeguards employees safety whilst reducing noise pollution. Identifying areas with excessive noise allows for correct safety protocols and equipment to be put in place, minimizing the risk of hearing damage and enhancing overall workplace well-being. Strategic layout adjustments can further mitigate sound pollution and optimize operational efficiency.

Light Levels

Monitoring light levels ensures energy efficiency, safety, and compliance within lighting regulations. By identifying unnecessary usage and leveraging natural light, businesses can reduce energy costs and promote sustainability. Moreover, maintaining appropriate lighting levels in manufacturing processes enhances safety and prevents long-term health issues associated with overexposure to bight light. Areas with high light levels, such as welding, should always be met with the appropriate PPE.

Contact our team for more information and discuss how it could benefit your business