factory monitoring for food and drink

factory monitoring for food and drink industries is key to cost management, process control, and environmental cleanliness.

Plug and Play Factory Monitoring for Food and Drink Industry

Gain instant insights into your energy, productivity, costs, and environmental performance.

Why Use Monitoring in the Food & Drink Industry?

🌡️Maintain Ideal Conditions

Track temperature, humidity, and air quality to meet food safety standards and maintain freshness across production and storage areas.

⚡Cut Energy Waste

Monitor power usage of chillers, ovens, compressors, and other equipment to find inefficiencies and reduce energy costs.

🔍Spot Issues Early

Catch problems before they impact operations—use vibration and temperature trends to identify failing motors, pumps, or fans.

📊Improve Compliance & Reporting

Automatically log environmental and equipment data to support compliance with food safety regulations and audits.

Taste The Benefits

Forget the clipboard and see your performance in seconds. With a plug and play monitoring solution you will have sitewide energy, machinery, and environmental data at the touch of a button.

Reduce Energy Costs

Pinpoint where energy is wasted and optimise efficiency

Minimise Machine Downtime

Catch faults early before they halt production

Ensure Regulatory Compliance

Meet HACCP and BRCGS standards with accurate monitoring

Increase Productivity

Understand performance bottlenecks and streamline processes

Support Sustainability Goals

Track your energy usage, environmental performance, and emissions

Make Data-Driven Decisions

Stop the hunch and gain a clear overview into your operations

The Tasting Menu: The Features

A smart solution packed full of flavour

Key Features of Our Monitoring Solution

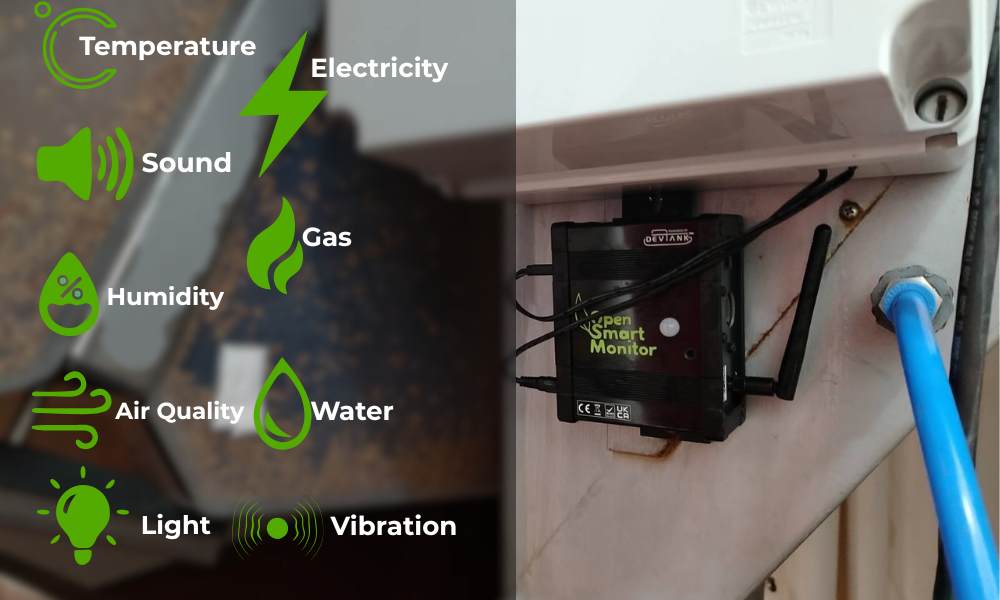

⚡Quick Installation

Set up your monitoring system in minutes with wireless sensors and non-invasive integration—no production delays.

📡Real-time Monitoring

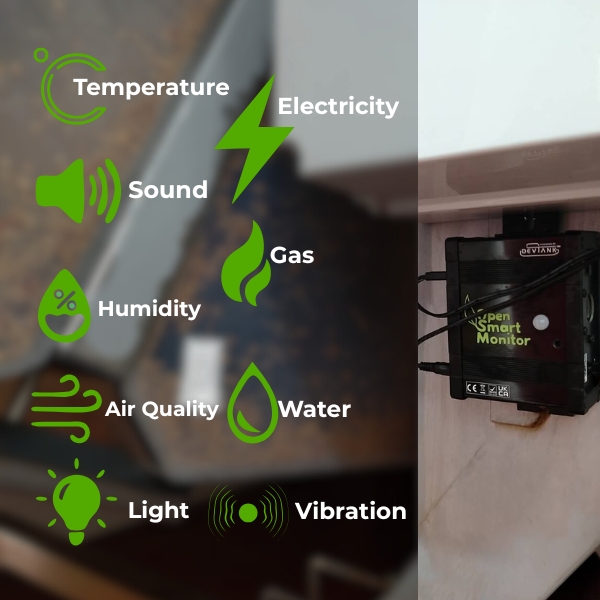

Track critical metrics like temperature, power, vibration, and air quality live across your facility.

🚨Automated Alerts

Receive instant notifications when readings go outside safe limits, enabling fast response and preventing issues.

🌐Browser-Based Platform

Access all data, dashboards, and reports securely from any device—no special software needed.

📈Historical Analysis

Use trends and past data to identify patterns, schedule maintenance, and continuously improve operations.

📦A Scalable System

Start small and grow your system with your business. Add more sensors or locations anytime without disruption.

The Selection Box

Pulse

Track your utilies in real-time, receiving instant insights into usage, waste, emissions, and costs.

Explore

Haven

Monitor your workplace environments and keep storage areas to the correct temperatures and humidity levels.

Explore

Sentinel

Receive insights into your machine health in order to reduce surprise breakdowns and improve productivity.

Explore

Hear From These Happy Bakers

Helen Yates - Luke Evans

Stay Compliant with Confidence

Our smart sensor technology helps food and drink businesses stay compliant with critical industry standards such as HACCP, BRCGS, SALSA, and ISO 22000. By providing continuous, real-time monitoring of key parameters like temperature, humidity, air quality, and energy usage, our solutions ensure that critical control points are constantly under observation. Automated alerts and secure data logging make it easy to maintain audit trails, demonstrate due diligence, and respond to deviations before they become issues. With our systems in place, you reduce manual processes, minimise risk, and streamline compliance reporting — all while maintaining full visibility across your production and storage environments.

Talk With Our Team

Our team are here to help you understand our solutions and how they can be of benefit to your business.