Already this year, we are seeing reports that manufacturers will be forced to cut jobs or/and production due to high energy costs. This comes after ministers finalised the details of a revised scheme, which will come to light as early as this week. Business (Businesses) within the UK already have energy cost support from the government, which is due to end in April. This ‘revised’ scheme is being planned to replace this, but will offer businesses significantly less financial support at times when most are struggling with rising costs.

Make UK, the UK’s trade body, gave this warning today and expect it to exacerbate planned reductions in headcount and production. Make UK’s analysing of a survey of top executives in the manufacturing industry (conducted with PwC) found that, almost three-quarters of companies expected their energy costs to increase this year. Two-thirds of these expect to have to reduce headcount or production, with similar numbers saying that the biggest risk to businesses and business confidence was that of energy costs.

Within the past few months, we have already seen the number of businesses, big and small, close their doors for good after their energy bills became too unsustainable. With this incoming warning from Make UK, do we expect this number to rise this year?

Source: Financial Times

So, how can OpenSmartMonitor help battle your unsustainably high energy bills?

In business, to keep yourself afloat at times of hardship, savings have to be made from somewhere. In our mind, this doesn’t always mean a reduction in headcount or production, but rather a reduction in your energy use. One aspect of this could be a change in the way your business works or an improvement to your building areas such as lighting. Does your building use standard bulbs or tube lighting? Changing these to LED bulbs/tubes can have a surprising impact. Have you considered changing shifts to take account of off peak energy tariffs or allowed people to work from home. With any changes you make, we have found data is key. Understanding the amount of energy you use and how you use it can provide so many answers which otherwise would go unseen. Energy monitoring, machine monitoring and environmental monitoring is how you can start collecting the most valuable data within your business.

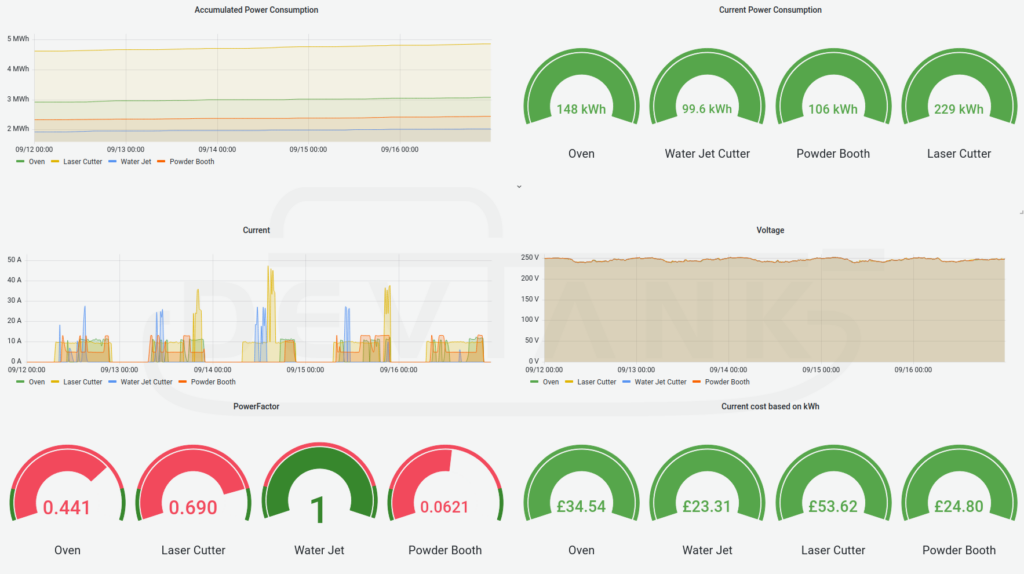

What does this mean? Energy monitoring is as it sounds, recording what energy you use every day. Machine monitoring will focus on individual items within a workplace, displaying how efficient they are, how much they are used and when they are using energy. Environmental monitoring simply records your workplace environment; sound, light, temperature, humidity and air quality. Adding all these types of data collections together will really display your areas of savings and areas of problems.

An installation of our ENV01 sensors can provide you with some surprising answers into where these energy costs come from and provide a tool for evaluating continuous improvements. We have already saved businesses money with the findings of; water leaks, inefficient machinery, machines and tools being left on when they aren’t in use, and even boilers being scheduled to come on overnight. One installation at Lindhurst Engineering suggests a saving of £25k a year in energy costs, just via data analysing! These examples are only a pinch of what our little box of magic can find!

Existing smart meters can be connected to the ENV01 to begin in-depth monitoring of your usage, but what can it show you that typical smart meters can’t? Typical smart meters will show your kWh usage with the calculated cost. ENV01 will show you this as well as enable you to analyse a range of parameters such as CO”e, Power Factor and load power modulation in greater depth with the use of a data dashboard. These dashboards display your live and collected data on a visible graph, with options to focus on different time frames and find possible anomalies. Hooking up CT-clamps to any of your machines will enable machine monitoring on top of meter monitoring, providing you an increased insight into your usage and costs. Maybe one or multiple machines aren’t running as efficiently as originally thought, or they are being left on when not in use.

On top of this, our sensors can monitor; Light levels, Sound levels, Humidity, Temperature and Air Quality. Temperature can tell you how well insulated your building is, or simply when your heating has been left on overnight. Monitoring light levels will alert you to any unnecessary use of lighting and quite possibly how much natural light enters a certain area of your building (do you need your lights on during the day?) The other environmental factors will make it easier for businesses to keep within any health and safety regulations, with the option of text/email alerts being setup to really watch your environment more closely.

On top of this, our sensors can monitor; Light levels, Sound levels, Humidity, Temperature and Air Quality. Temperature can tell you how well insulated your building is, or simply when your heating has been left on overnight. Monitoring light levels will alert you to any unnecessary use of lighting and quite possibly how much natural light enters a certain area of your building (do you need your lights on during the day?) The other environmental factors will make it easier for businesses to keep within any health and safety regulations, with the option of text/email alerts being setup to really watch your environment more closely.

Once you have collected enough data to start an in-depth analysation of your business, a wealth of possible savings will be presented to you. Whether that will be issues like water leaks, faulty machinery, boilers, or simply changing certain aspects such as the kind of lighting you use, moving shift patterns or better insulation, it will all be the key to lowering your energy costs and your carbon footprint.