Manufacturing

Factory Environmental Monitoring

Paying attention to environmental factors is crucial in manufacturing. Areas such as spraying booths, steelworks, woodwork, and welding can produce harmful pollution that can affect everyone involved. Proper ventilation or personal protective equipment (PPE) is necessary to ensure the safety of all employees. Regular air quality monitoring in these areas can help maintain a secure workplace and assess the effectiveness of ventilation. Furthermore, monitoring sound levels can help identify areas that require hearing protection and make modifications to reduce noise pollution, which can increase staff safety.

Productivity in factory settings can be affected by high temperatures and humidity, causing discomfort for employees. Working in high temperatures and bad humidity levels can cause headaches and dry mouths, making it harder to work efficiently. These factors can also harm the building by drying out walls or causing mold. To keep everyone comfortable and safe, it’s best to maintain humidity levels between 45% and 60% and ensure that temperatures are comfortable.

Temperature

ENV01 incorporates onboard temperature and humidity as well as an external probe allowing you to measure the temperature of what you require such as; room temperature, temperature of machinery, or the temperature of certain components.Sound

If your company has a noisy environment due to heavy machinery use this parameter to record exactly how loud it gets and alert you if thresholds are exceeded. This can be used to maintain sound regulations in the workplace.Light

Monitoring light levels through the onboard sensor provides an assessment of the installed location.Air Quality

Air Quality is important especially when working in production and manufacturing. Continuous monitoring of airborne particles provides health and safety benefits. This sensor can measure PM2.5 and PM10 particulates.Humidity

Humidity can effect many things including corrosion and contamination. Keeping an eye on how humid your workspace is can help.Contact our team for more information and discuss how it could benefit your business

Energy and Machine Monitoring

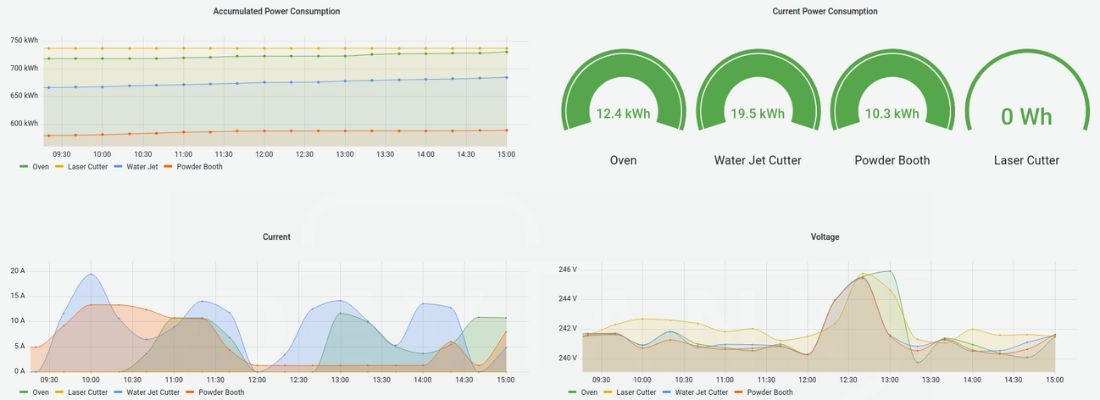

Factories require a significant amount of energy to operate their machinery and tools. However, keeping track of your energy, water, and gas consumption can provide valuable insights and help identify areas where costs can be reduced. Detecting leaks in your water and gas systems is particularly important, as they can go unnoticed for months and cost businesses hundreds, if not thousands, of pounds. Early detection of leaks can save a considerable amount of money. Monitoring electricity usage is also crucial within manufacturing, as it allows you to identify equipment that is left running overnight, such as heating and lighting. By monitoring your machinery and tools, you can pinpoint where your costs are coming from and improve efficiency. Machine monitoring is a useful tool for determining if your machinery is running efficiently and if they are costing more than expected.

Predictive Maintenance

To ensure efficient machine monitoring, it’s crucial to prioritize predictive maintenance. By taking a proactive approach to schedule maintenance and repairs, you can save a significant amount of time and money. With predictive maintenance, you can identify potential problems before they occur, avoiding costly downtime and production delays. Automating alerts based on specific parameter readings is an effective way to detect and diagnose issues early on, streamlining the entire maintenance process.

Order your OpenSmartMonitor sensor via the Devtank website.

Case Study

Acres Engineering needed a way to monitor their electricity consumption, manufacturing equipment, and general environmental monitoring across their workspaces. In particular, they were interested in measuring their air quality, noise levels, and machine energy usage to try to create a better working environment and lower their energy costs. Four ENV01 sensors were installed and are now being used across their site to monitor environmental parameters, energy usage, as well as machine monitoring. They are now able to lower the amount of waste and reduce their energy bills, whilst also monitoring their air quality, sound, light, temperature, and humidity to improve their workplace health and safety.

Contact our team for more information and discuss how it could benefit your business