& Predictive Maintenance

Predictive Maintenance and Remote Monitoring

Our sensors have been built for the most effective way of use and using a browser-based dashboard is a major part of this. This enables you to view your data at anytime, on any device, wherever you are. Being able to remotely monitor your business environmental and equipment, gives you the freedom to review your data when it matters most. An even better use for remote monitoring comes with your work being widespread across the country or even countries.

See our live demo and see how remote monitoring looks like and works.

Contact our team for more information and discuss how it could benefit your business

Use Parts To Their Fullest

With a better scheduling of maintenance, parts will be used to their fullest and will stop being replaced too early. This boosts up your machines sustainability by not wasting good parts as “I’m here so I will change it now”.

Higher Productivity

By remotely monitoring and ultimately enabling predictive maintenance, you will see less machine breakdowns and be able to better schedule in repairs improving productivity.

Save time and Money

In business with multiple sites it can be costly and time consuming traveling to them all to carry out maintenance checks and repairs. By remotely monitoring and through the use of predictive maintenance you will save time and money by only sending your maintenance teams when it’s required.

Order your OpenSmartMonitor sensor via the Devtank website.

Predictive Maintenance

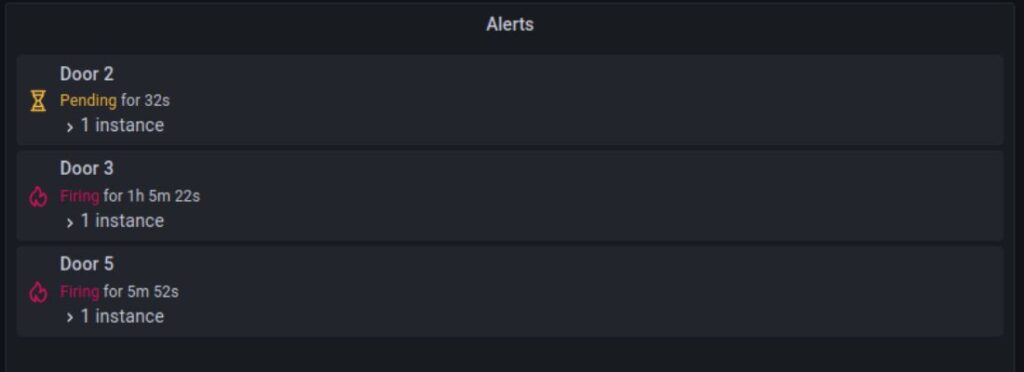

Machine monitoring and remote monitoring perfectly with predictive maintenance as the above case study shows. By remotely monitoring your business and equipment, you can better predict when maintenance is required. With more knowledge and data to better understand the piece of equipment being maintained, the more automated your maintenance schedule can become. Setting up alerts for parameters and wear of certain machinery, with a greater understanding of when maintenance needs to be done, can make it easier and cheaper to maintain machines.

Case Study

BGB operates wind farms in various locations throughout the UK and needed to improve its process for monitoring the sites. They required a more efficient and cost-effective solution for checking the condition and performance of each turbine. In the past, engineers had to travel to each site periodically and climb up each turbine to check and maintain them, which was time-consuming and often unnecessary. Maintaining the brushes inside each turbine is crucial for preventing potential failures or fires. To solve these issues, we customized our OpenSense sensors for BGB’s use, enabling remote monitoring of each turbine’s environmental conditions and brush wear. This implementation has allowed BGB to remotely monitor their sites, predict and plan maintenance schedules, and save time and money. Additionally, automated alerts are in place to notify BGB when a brush needs replacing.

Order your OpenSmartMonitor sensor via the Devtank website.

Data Time Ranges

Our dashboards enable our customers to look back at their historical data which is a key feature to gaining better insights into your energy usage and environmental improvements.

Contact our team for more information and discuss how it could benefit your business